- Home

- Total Solution

- For Aluminum Composite Panel

Total Solution for Aluminum Composite Panel

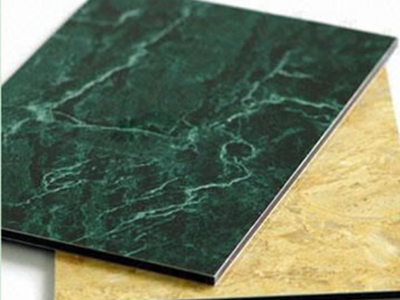

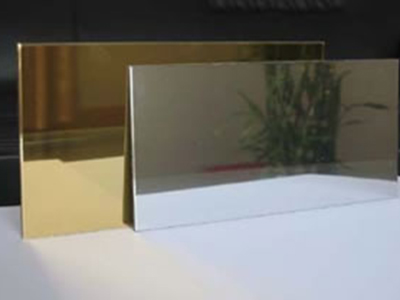

Aluminum composite panels can be manufactured with different functions to satisfy customers' specified needs. For example, there are aluminium composite panels with functions like fireproofing, anti-bacteria, and antistatic, etc. Classifying by surface treatment, there are granite aluminium composite panels, brush finish aluminium composite panels, mirror finish aluminum composite panel, and baking finished aluminum plastic panels, and more. With regard to applications, composite aluminium panels can be used both for decorating external walls and internal walls.

Aluminum composite panels are made from aluminum alloy and plastic. Hence, they are also called composited aluminum and plastic decking. They feature high hardness, light weight, and smooth surface.

Aluminum plastic composite panels can be manufactured into different sizes, shapes, and colors and styles, to offer more options for architectural designs.

Due to its light weight and high hardness, this type of decorative building material is very popular around the world.

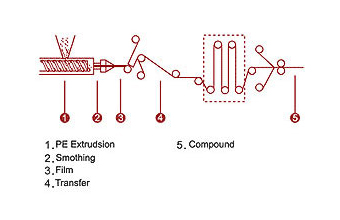

- Production steps

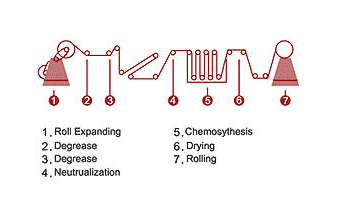

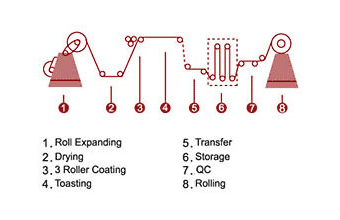

(1) PE extrusion

(2) Smoothing

(3) Film coating

(4) Transfer

(5) Laminating - The detailed introduction of the primary production equipment

Continuous laminating line is the key equipment for producing our aluminum composite panels. The laminating line can produce a high temperature and high pressure environment, which functions to make aluminium materials, PE core materials, and polymer films tightly adhesive to each other. Thus, the panel surface is smooth, and the panels are easy to be peeled off.

We adopt high quality polymer films, advanced production equipment, and leading technologies as well as strict quality control to guarantee product quality. Now, the quality index of our aluminum composite panel is higher than that of imported composite panels.

- General description

Jixiang Building Materials Corp. is primarily specializing in marketing and manufacturing aluminium composite panels under the trademark of ZWM, Jiangxiang Jiamei, Jixiang Siji, Shenzhou Jixiang, and Jinmu, etc. All purpose adhesive, super glue, silicone sealant, and aluminium plate, etc. can also be provided here. - Classification

As we have mentioned before, our aluminum composite panels fall into five primary categories, that is, internal wall panels, external wall panels, wooden grain panels, granite panels and fire resistance panels. There are totally hundred of types of aluminium plastic composite panels, with variety of colors for your option. - Raw materials and production techniques

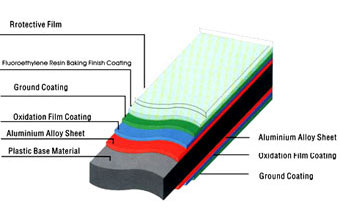

Composed of superior quality antirust alloy sheets and high intensity polyethylene core sheets, and coated with world-class fluorocarbon resin, the aluminum composite panel quality is highly ensured. Additionally, our composite panels are made strictly in accordance with international standard ACP production standard.

Relying on our adoption of high quality raw material and advanced production techniques, all our aluminum composite panels feature strong weather resistance, uniform coating, smooth and even surface, and more.

- Protective film

- PVDF clear coating

- PVDF top coating

- PVDF primer

- Chromate treatment

- Aluminum skin

- Chromate treatment

- Bonding lamination layer

- Nontoxic PE core material

- Optional fire resistant and nontoxic PE core material

- Optional back coating

- Economy

Due to our adoption of high quality coatings, our aluminum composite panels are dispensed with frequent maintenance, thus saving a lot on maintenance cost. Hence, our composite panels are good decorative building material for high-rise buildings.

With regard to cities and regions with serious environment pollution, it is recommended to clean and maintain aluminium composite panels in a few years' time. Our panels are easy to be cleaned. They can be cleaned by neutral cleaning agent and clean water, and come out to be fairly new after cleaned. - Durability

Fluorocarbon coated aluminum composite panels are characterized by long service life, good weather resistance, high heat resistance and wear resistance, and good resistance to pollutions, and more. - Flatness

Our aluminum composite panels are manufactured with smooth and even surface, which can satisfy people's high demand on the appearance of modern constructions. - Light weight

By adopting light-weight aluminium alloy and superior quality plastics as primary raw material, aluminum composite panel is lighter than other types of decorative construction material. Hence, it is easy to install and needs shorter installation period. - Easy installation

Our aluminium composite panels are adaptable to various decoration requirements, because they are easy to be cut, grooved and bended. - Fireproofing

The exterior aluminium sheet of aluminum composite panels can effectively protect interior PE core material, because it can prevent heat conduction at the initial stage of combustion. The flame resistance of our aluminum plastic composite panels has reached international standard. - Design performance

Aluminum composite panels can be made into different colors and styles, thus satisfying the diversified design requirements of architects. - Eco-friendliness

The surface coating is durable and has no changes, which produces no pollutants.

- Wall and interior decoration of air ports, docks, stations, metros, hotels, restaurants, recreation places, top-grade residence, villas, office, and many other buildings.

- Big billboards, shop windows, roadside news kiosks, bookstalls, telephone booths, traffic sentry boxes and filling stations.

- Internal walls, ceilings, compartments, kitchens, toilets, etc.

- Decoration for shops, cabinets, pillars, furniture, trains, automobiles, ships and carriages, etc.

- Renovation and reconstruction of old buildings.

- Cleaning and dust control projects.

As a professional aluminum composite panel manufacturer, we can also manufacture aluminium plates, aluminum foil, silicone sealant, and all purpose adhesive, etc. In addition to high quality products, we can also produce complete services. For example, we can provide three year quality warranty for our PE aluminum composite panels and ten year warranty for PVDF aluminum composite panels.

Presently, our products have been ISO9001:2000 certified. Thanks to reliable quality, our building materials have been used in Russia, Saudi Arabia, Iran, India, Singapore, and Indonesia, and more.

Welcome both national and international customers to choose our products.

Company Brief: Jixiang Building Materials Corp. is a specialized decorative construction material manufacturer in China. Located in Songjiang district, Shanghai, China, our headquarters occupy an area of over 53,000m2 and have a total building area of 90,000 m2. We primarily manufacture PE aluminum composite panel, PVDF aluminum composite panel, aluminum foil, and construction adhesives, like all purpose adhesive, silicone glue, and more. Our high quality products have made us one of the members of the China Building Materials Federation. Over the years, we have developed into a large shareholding enterprise with following subsidiaries: Zhengzhou Climb Decoration Materials Co., Ltd., Zhengzhou Better Adhesives Co., Ltd., Zhejiang Liantai Instruments Co., Ltd., Yueqing Zhongtian Plastic Industry Co., Ltd., Yueqing Zhongtian Instruments Co., Ltd. and Shanghai Jiuzhi Paint Co., Ltd.

Request a Quote? Feel free to contact us at any time!

click here