- Home

- Total Solution

- For Coated Aluminum Coil

Total Solution for Coated Aluminum Coil

| STYLE NO. | SPECIFICATION | COATED BY PE | COATED BY PVDF | BACK COATING | NOT COATED | |||

| A | B | A | B | C | ||||

| 1 | 0.022 | √ | √ | √ | ||||

| 2 | 0.024 | √ | √ | √ | ||||

| 3 | 0.026 | √ | √ | √ | ||||

| 4 | 0.03 | √ | √ | √ | √ | |||

| 5 | 0.04 | √ | √ | √ | √ | |||

| 6 | 0.05 | √ | √ | √ | √ | |||

| 7 | 0.06 | √ | √ | √ | √ | |||

| 8 | 0.07 | √ | √ | √ | √ | |||

| 9 | 0.08 | √ | √ | √ | √ | |||

| 10 | 0.09-0.10 | √ | √ | √ | √ | |||

| 11 | 0.12 | √ | √ | √ | √ | |||

| 12 | 0.15 | √ | √ | √ | √ | √ | √ | √ |

| 13 | 0.18 | √ | √ | √ | √ | √ | √ | √ |

| 14 | 0.2 | √ | √ | √ | √ | √ | √ | √ |

| 15 | 0.25 | √ | √ | √ | √ | √ | √ | √ |

| 16 | 0.28 | √ | √ | √ | √ | √ | √ | √ |

| 17 | 0.3 | √ | √ | √ | √ | √ | √ | √ |

| 18 | 0.35 | √ | √ | √ | √ | √ | √ | √ |

| 19 | 0.38-0.4 | √ | √ | √ | √ | √ | √ | √ |

| 20 | 0.43-0.45 | √ | √ | √ | √ | √ | √ | √ |

| 21 | 0.48-0.50 | √ | √ | √ | √ | √ | √ | √ |

A(PE): white,milk white, ivory white, dull white, light blue, light green, grey, dark grey etc.

B(PE): flash silver, champagne, white silver grey, flash gold, black, blue grey etc.

A(PVDF): white,milk white,ivory white,dull white, light blue,light green, grey, dark grey etc.

B(PVDF): flash silver, champagne, white silver grey etc.

C(PVDF): red, dark blue, silver blue, copper brown etc.

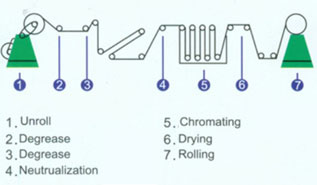

Production processes for aluminum foil rolls

Chromating Line

1. Unwinding

2. Degrease (brush)

3. Degrease (dipping bath)

4. Neutralization

5. Chromating

6. Drying

7. Rewinding

The chromating line, a kind of surface treatment line, functions to clean the lubricating grease, anti-oxidization grease, silicon, magnesium, copper and many other impurities on the surface of aluminum foil.

During chromating for our aluminium foils, we acquire high quality chemical raw materials and technologies from Germany Henkel Group to guarantee surface treatment quality. After surface treatment, the aluminium foil surface will be covered with a layer of high intensity honeycomb-style oxide film. This oxide film functions as an agent to make paint and aluminum foil adhesive with each other.

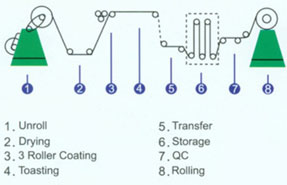

Precision coating line

1. Unwinding

2. Drying

3. 3-roller coating

4. Baking finish

5. Transfer

6. Storage

7. QC

8. Rewinding

The precision line functions to coat paints on chromated aluminum foil rolls. We adopt high precision three-roll reverse coating machines to conduct surface coating in enclosed and dust free environment. Thus, the coating thickness and coating quality can both be guaranteed.

The oven is divided into four temperature-controllable sections. This ensures the optimum condition of surface coating's solvent resistance, hardness, and flexibility, etc. Hence, our surface coated aluminum foil coils are characterized by high glossiness, strong adhesive force and corrosion resistance.

Company Brief: Jixiang Building Materials Corp. is a specialized decorative construction material manufacturer in China. Located in Songjiang district, Shanghai, China, our headquarters occupy an area of over 53,000m2 and have a total building area of 90,000 m2. We primarily manufacture PE aluminum composite panel, PVDF aluminum composite panel, aluminum foil, and construction adhesives, like all purpose adhesive, silicone glue, and more. Our high quality products have made us one of the members of the China Building Materials Federation. Over the years, we have developed into a large shareholding enterprise with following subsidiaries: Zhengzhou Climb Decoration Materials Co., Ltd., Zhengzhou Better Adhesives Co., Ltd., Zhejiang Liantai Instruments Co., Ltd., Yueqing Zhongtian Plastic Industry Co., Ltd., Yueqing Zhongtian Instruments Co., Ltd. and Shanghai Jiuzhi Paint Co., Ltd.

Request a Quote? Feel free to contact us at any time!

click here