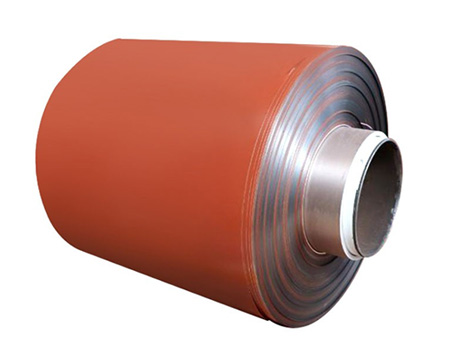

In the part of aluminum composite materials (ACM panel) processing, JXG also manufactures aluminum sheet coils. We can offer trim coils and coated coils with different colors, which are available in stock. Customizing is available upon request

The materials from different aluminum ingots such as 1100 series, 3003 series and 5005 series undergo cold or hot rolling and quenching to produce the aluminum coils which are then coated to meet customer's need.

Size: aluminum coil we can manufacture

- Thickness: 0.02mm - 0.60mm

- Width: 1,240mm, 1,270mm, 1,520mm, 1,570mm, etc.

- Color: We offer standard colors, as well as custom color options.

- Max Diameter: 1,200mm

- Weight: 2.5 ton/coil; 3 ton/coil

- Interior Diameter: 505mm or 405mm

Any color can be provided by computer blending

Our factory has three advanced automated coating lines that meet or exceed all relevant national standards for performance.

If you are looking for eco-friendly building materials, ZWM is your best choice.

As a result of our efforts, we have become one of the leading building material exporters and suppliers in China. Shanghai Jixiang Building Materials Group now has over 50 distributors, and we have created four primary brands, ZWM, Jixiang Jiamei, Jixiang Siji, and Jinmu. You can find our decorative construction materials under these brand names in a wide range of countries, including Russia Saudi Arabia, Iran, India, Indonesia, Singapore, and more. So, if you are looking for eco-friendly decorative materials for either interior or exterior building decorations, please contact us.

As a result of our efforts, we have become one of the leading building material exporters and suppliers in China. Shanghai Jixiang Building Materials Group now has over 50 distributors, and we have created four primary brands, ZWM, Jixiang Jiamei, Jixiang Siji, and Jinmu. You can find our decorative construction materials under these brand names in a wide range of countries, including Russia Saudi Arabia, Iran, India, Indonesia, Singapore, and more. So, if you are looking for eco-friendly decorative materials for either interior or exterior building decorations, please contact us.